We created these products with one goal:

To keep them out of the landfill.

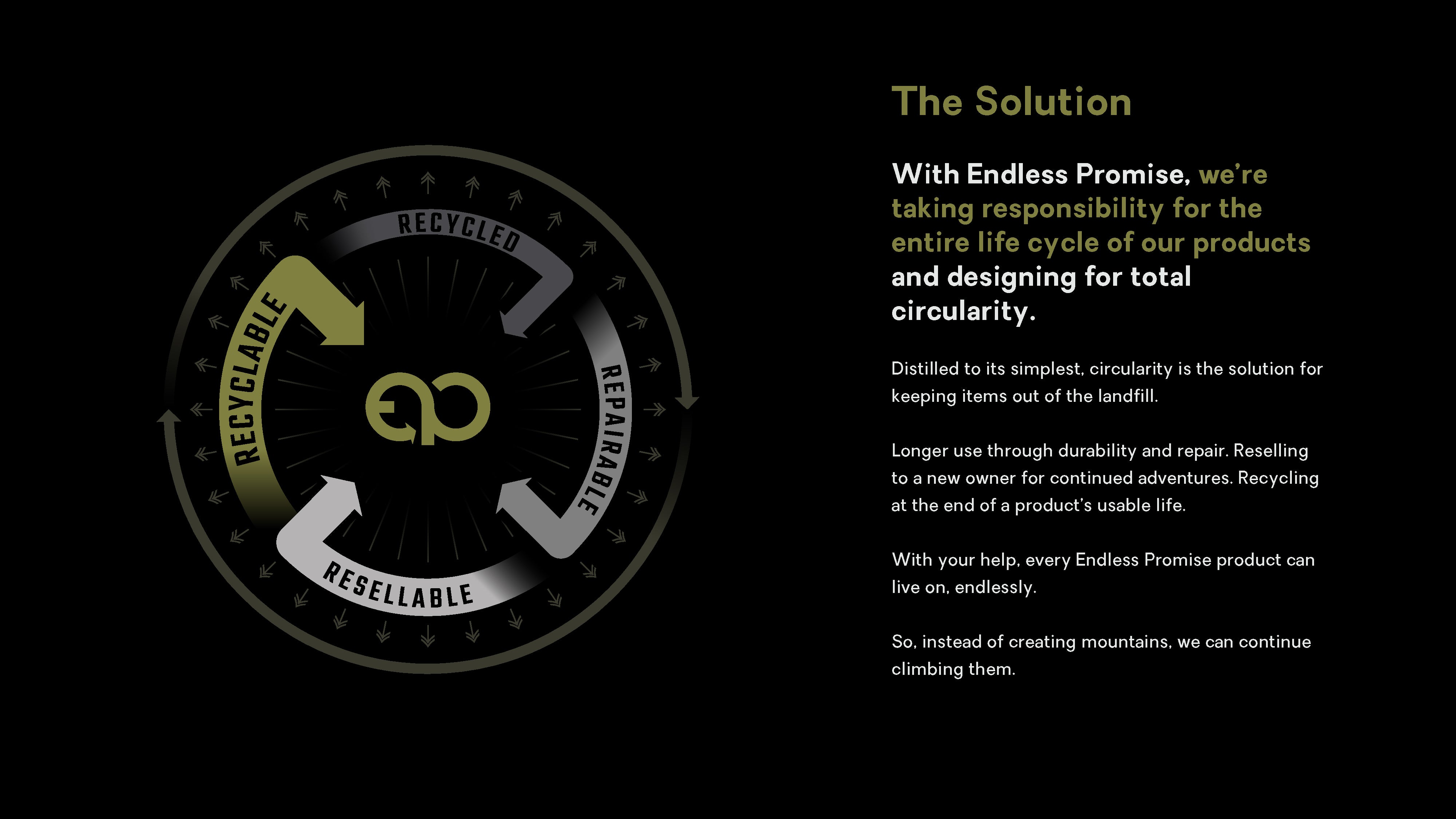

Each item in the Endless Promise collection is painstakingly engineered for total recyclability.

That way, once this gear has accompanied you on its lifetime of adventures, it can easily become something new.

This is just one step in our effort to take full responsibility for what we make, from beginning to end.

Because with Endless Promise, there doesn't have to be an end.

Recyclability Is the Toughest Piece of the Puzzle

Unfortunately, you can’t just toss old sleeping bags or backpacks into the recycling bin along with your empty cans and bottles.

We knew the key to making a successful recyclable product was making an easily recyclable product, and that meant a mono-polymer approach was needed.

Mono-polymer design means creating a product that’s nearly entirely made from a single material family. (Currently, the easiest consumer goods material to recycle is polyester, so that's where we set our sights.)

While basic outdoor gear might typically use anywhere from a half-dozen to a dozen different materials, we have to simplify our Endless Promise designs down to just a few.

We knew the key to making a successful recyclable product was making an easily recyclable product, and that meant a mono-polymer approach was needed.

Mono-polymer design means creating a product that’s nearly entirely made from a single material family. (Currently, the easiest consumer goods material to recycle is polyester, so that's where we set our sights.)

While basic outdoor gear might typically use anywhere from a half-dozen to a dozen different materials, we have to simplify our Endless Promise designs down to just a few.

The development of Forte™, a sleeping bag, was hard. The development of two very technical backpacks, in comparison, was like going from a 5.11 indoor climbing route to free soloing El Cap.

But like all design challenges in NEMO history, our team responded with innovative solutions. These solutions not only met the sustainability standards, but they also surpassed our sky-high performance ones. In developing our Endless Promise® packs, we’ve introduced two new materials that make these products better on the trail and better for the user. We also integrated repairability into the patterning of the packs themselves, so they can stay on the trail longer.

But like all design challenges in NEMO history, our team responded with innovative solutions. These solutions not only met the sustainability standards, but they also surpassed our sky-high performance ones. In developing our Endless Promise® packs, we’ve introduced two new materials that make these products better on the trail and better for the user. We also integrated repairability into the patterning of the packs themselves, so they can stay on the trail longer.

Even with products that were technically recyclable, however, our work wasn’t done. We had to ensure there was a place to send our products when they had reached the end of their adventures — a place that could process and ultimately break down the gear into new, usable material.

For Forte, we found the right partner with Unifi, a U.S.-based recycler that was excited to accept this challenge. Unifi is known for their REPREVE® yarns, which are created from recycled plastic and used in everything from shoes to tent pole bags. For our down bags, Allied Feather + Down in Los Angeles can extract the down from the bags and then send the remaining material to Ambercycle, an advanced chemical recycler also in Los Angeles that can break things down to a molecular level for a stronger, infinitely recyclable new material.

Through these partnerships, and the support of Endless Promise® customers, we hope to one day produce new products made from our old ones.

For Forte, we found the right partner with Unifi, a U.S.-based recycler that was excited to accept this challenge. Unifi is known for their REPREVE® yarns, which are created from recycled plastic and used in everything from shoes to tent pole bags. For our down bags, Allied Feather + Down in Los Angeles can extract the down from the bags and then send the remaining material to Ambercycle, an advanced chemical recycler also in Los Angeles that can break things down to a molecular level for a stronger, infinitely recyclable new material.

Through these partnerships, and the support of Endless Promise® customers, we hope to one day produce new products made from our old ones.

The Elements of an Endless Promise® Product

Endless Promise® in the Press

Popular Science

The 50 Greatest Innovations of 2023

REI's Good Gear

How NEMO Made its Top-Selling Sleeping Bag Fully Recyclable

Gear Junkie

Recycle This Sleeping Bag: Forte Endless Promise Sleeping Bag Review

Our Partners